Application

An ISO 9001:2015 Certified Company

Some Applications Below:

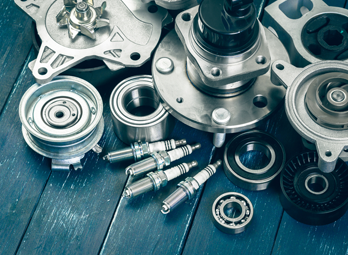

Automotive Parts

Camera

Clamps

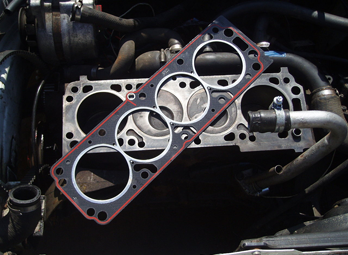

Engine Gasket

Fiber Optics

Floppy Disks

Food Processing

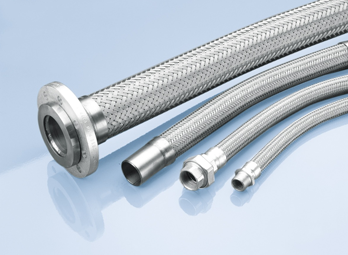

Metal Hose

Needles

Pens

Piston Rings

Thermometer

Watch bands

Heat Exchangers

Typical Application

Tubes, Pipes, Cutlery, Utensils, Automobile parts, Kitchen Sinks, LPG Gas Stoves, Electronic Components, Furniture, Decorative Applications, Structural fabrications and other similar applications.

| Grade | Characteristics | Typical Applications |

| 301 Austenetic |

Able to attain high strength and ductility through moderate or severe Cold Working. |

|

| 304 Austenetic |

Excellent corrosion resistance & forming characteristics. |

|

| 304L Austenitic |

Low Carbon level (0.03 max.) Improved resistance to intergranular corrosion. |

Used for parts and structures which can not be heat treated for stress relieving after welding less tendency to work hardening. |

| 310S Austenitic |

High Creep strength and mechanical properties at higher temperature |

|

| 316 Austenitic |

2-3% Mo which improves Austenitic corrosion resistance to halogens and imports hot strength characteristics resistance to pitting corrosion. |

|

| 316L Austenitic |

Reduced tendency towards carbide precipitation. |

For parts which cannot be heat treated after welding. |

| 321 Austenitic |

Similar to 304 but tabilized with Titatnium to avoid intergranular corrosion. Resists sealing and vibration fatigue. |

|